Independent Eyewear Manufacturing (IEM) is an American company that is part of the Europe Eyewear group and specializes in the artisanal production of acetate eyewear. Founded in 2014, it is headquartered in Vernon Hills, Illinois.

SCROLL

All production data collection and analysis activities were performed manually. This meant that workers and managers had to transcribe information on paper or in spreadsheets, a method that not only required a significant expenditure of time and resources, but was also subject to errors and inaccuracies. In addition, the lack of an automated system slowed communication between departments, causing delays in production and difficulty in identifying inefficiencies.

Without a digital monitoring system, IEM was unable to obtain real-time data on the status of production. This meant limited control over the costs of individual production phases and inefficiencies in the various departments. Any problem, such as a malfunction of the machinery or a delay in production, could only be identified after hours or days, compromising the company's reactivity and the ability to intervene promptly to resolve critical issues.

Every production order had to be accompanied by detailed paper documentation, including style and color specifications. This manual process was not only slow and inflexible, but also increased the risk of errors and misalignments in production stages. Each change or update required reprinting new documents, increasing resource consumption and the risk of delays. The lack of an integrated digital system also hindered order tracking and the efficient management of customized customer requests.

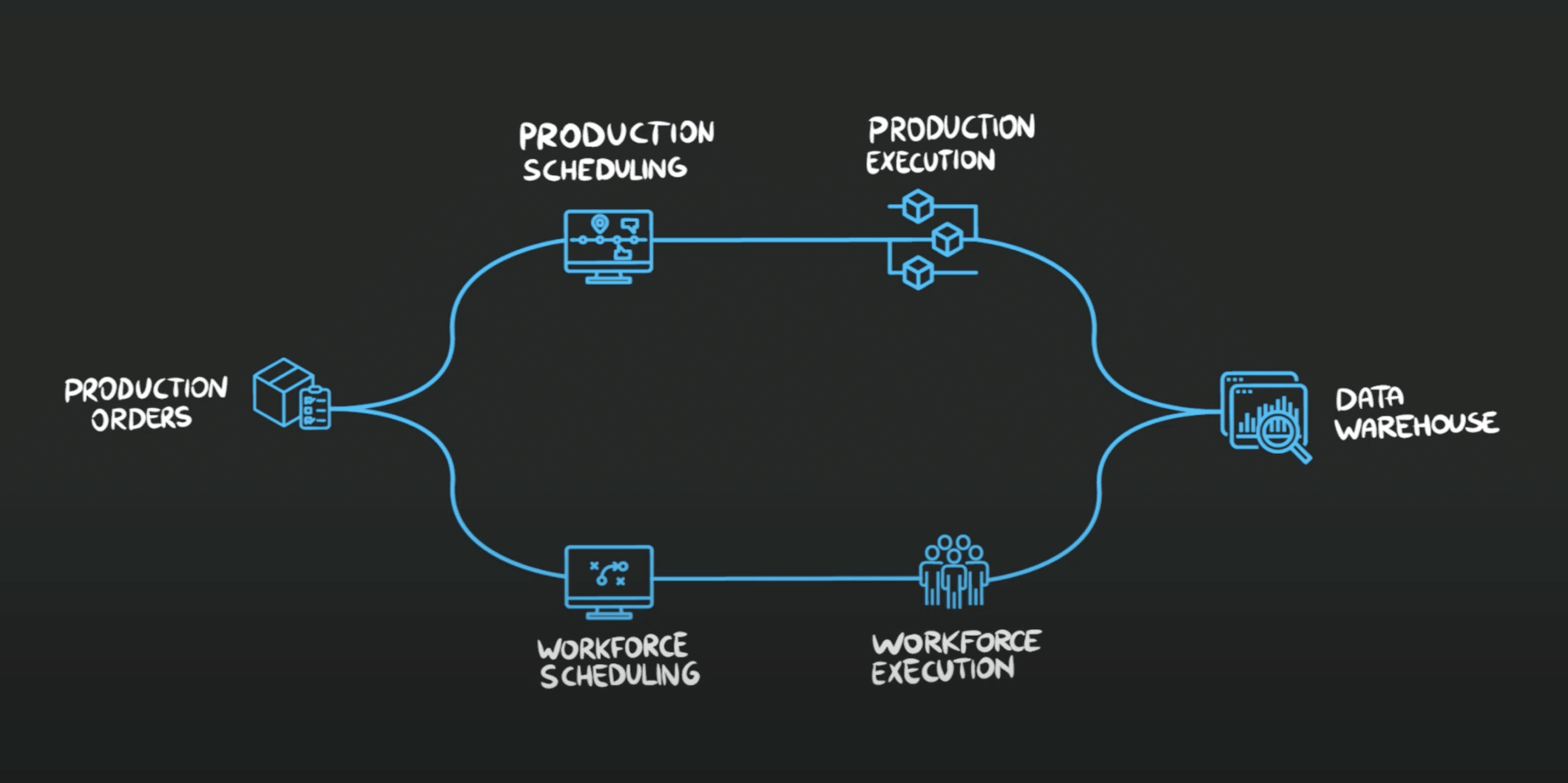

AzzurroDigitale has developed a tailor-made digital transformation for IEM, divided into different phases:

To overcome the difficulties related to manual process management, Azzurro MES was implemented, a Manufacturing Execution System (MES) that allows real-time monitoring of production. Thanks to the installation of tablets and interactive totems directly in the factory, operators can view the progress of orders at any time, record activities, report problems and receive updated instructions. This has allowed IEM to eliminate dependence on paper documents and improve operational efficiency, reducing errors and ensuring more precise control over the production flow.

Workforce management was one of the main challenges for IEM, especially in shift planning and assignment of tasks based on skills. The introduction of AWMS (Advanced Workforce Management System) has allowed them to optimize workforce management, ensuring a more equitable distribution of workloads and dynamic planning of tasks. The system takes into account constraints such as holidays, unexpected absences and employee experience levels, ensuring that each stage of production is covered by the right resources at the right time.

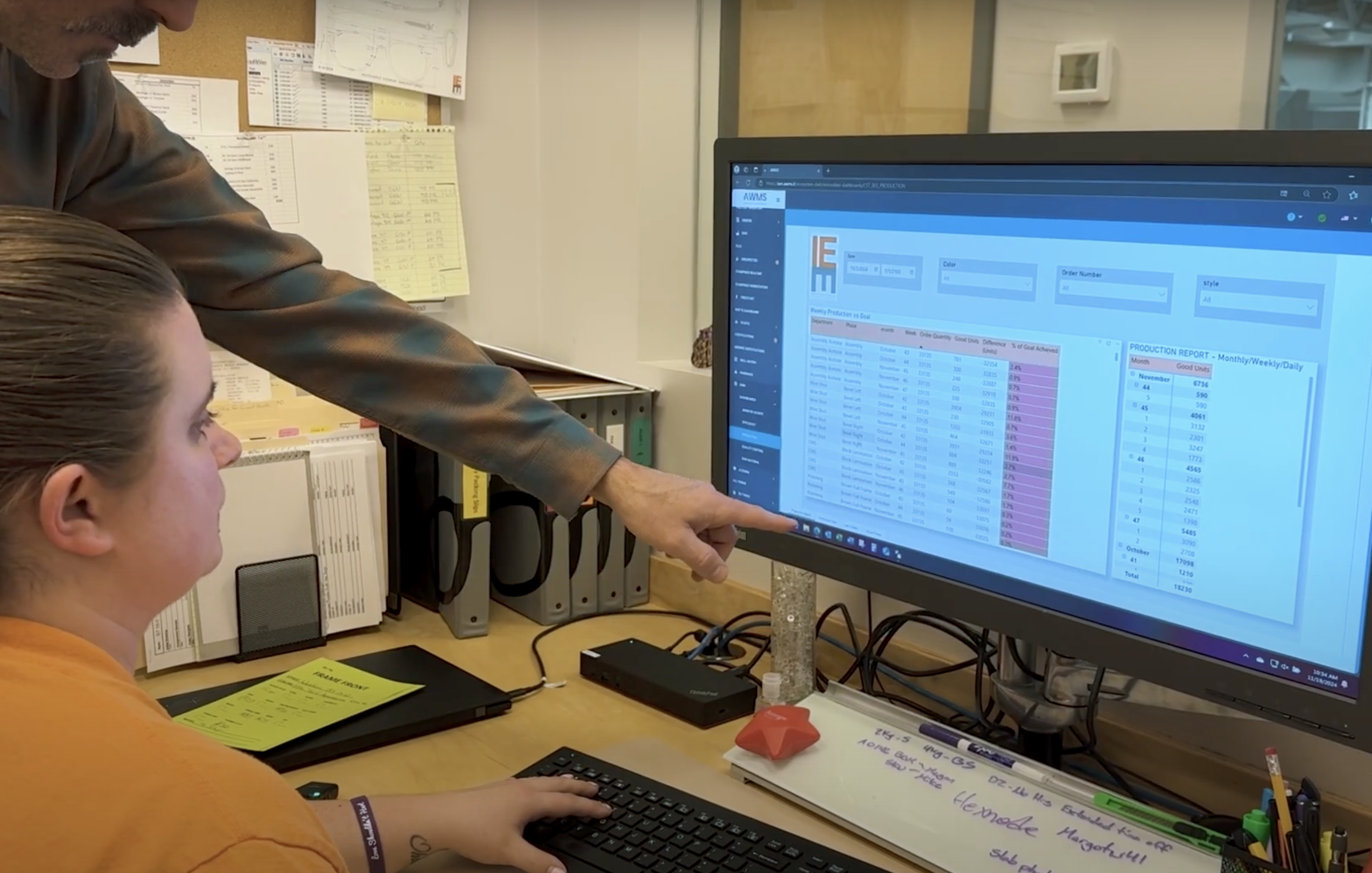

To improve decision making and provide a clear view of business performance, Power BI, an advanced business intelligence platform, has been integrated. Thanks to the automated collection and analysis of data from all production areas, IEM management can now monitor key KPIs such as operational efficiency, production costs and cycle times. Customized dashboards allow you to view real-time information, identify trends and make decisions based on concrete data, improving responsiveness and the ability to optimize production processes.

Thanks to the digital transformation implemented with AzzurroDigitale, IEM has significantly improved operational efficiency and production management. Process automation has reduced manual errors and improved communication between departments, ensuring a smoother and more coordinated workflow.

Real-time visibility into operations has allowed inefficiencies to be quickly identified and acted upon, reducing waste and delays. In addition, optimizing personnel management has improved workload balance, increasing employee well-being and overall productivity. Finally, thanks to structured data and interactive dashboards in Power BI, management now has access to detailed insights that support faster, data-driven strategic decisions, driving sustainable growth and greater competitiveness on the market.

Now we can see the data in real time. It is constantly updated throughout the day and allows us to understand which departments are operating under-efficiently, how much each piece costs and which processes we need to focus on to improve.

Write to us about what you need! Together we will identify the best solution for your needs.

"*" indicates required fields

Via della Croce Rossa, 36

35129 – Padua

* Applications sent to this email will not be considered