With over sixty years of experience in the sector, Aristoncavi is one of the main Italian manufacturers of rubber-insulated electrical cables, specialized in low and medium voltage solutions. It is recognized as a leader in some highly specialized market segments, thanks to a deep expertise in the design and production of cables for special applications, intended for sectors such as industrial, energy, railway and naval.

SCROLL

In Aristoncavi’s production process, the production of certain types of cable was critically linked to the know-how of some expert operators or to the exclusive use of specific machinery. This dependence entailed a real risk: in the event of the absence of the reference operator or unavailability of the machinery, the entire process could slow down or even stop. The company therefore needed to make the production flow more flexible and resilient, ensuring continuity even in non-ideal conditions.

Each operator in Aristoncavi has a unique set of experiences and technical skills, acquired over time directly in the field. However, this knowledge was largely kept at an individual level, making it difficult to transmit to the rest of the team. The goal was to transform this operational knowledge into a shared, accessible and structured heritage, in order to make the department more autonomous, cohesive and efficient. The challenge was to do it in an automated way, avoiding dependencies on informal training processes or on the availability of individuals.

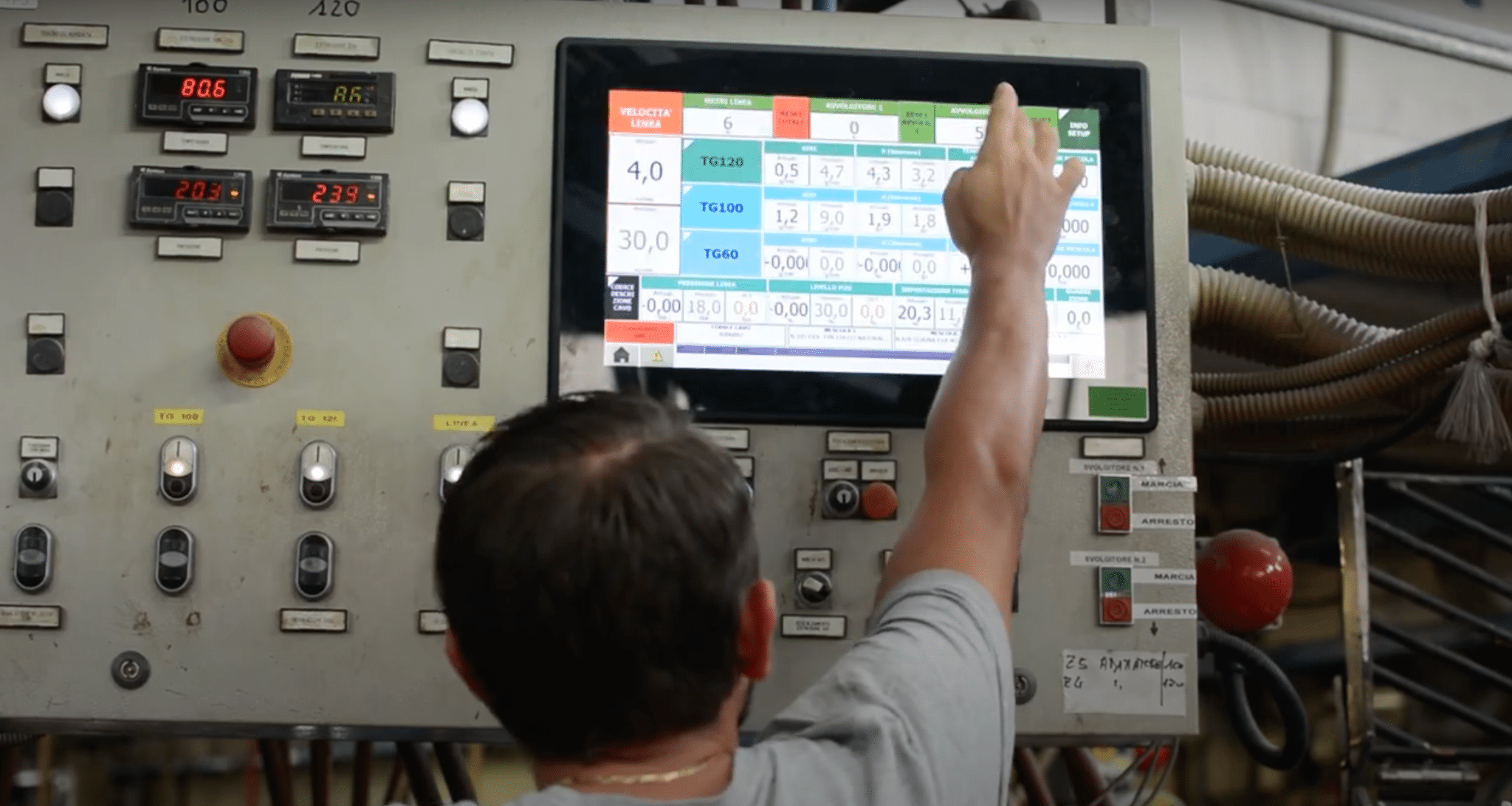

To meet Aristoncavi’s needs, we developed and implemented a custom software solution capable of digitizing and making machine setup operations shareable. The system revolves around a Panel PC installed on board the machine, through which operators can enter, save and recall the technical production specifications of each cable, making them immediately accessible from any other machine within the plant.

This architecture allows to overcome the dependence on single operators or specific machines: each line can access the production “recipe” autonomously, ensuring continuity and standardization in the production process.

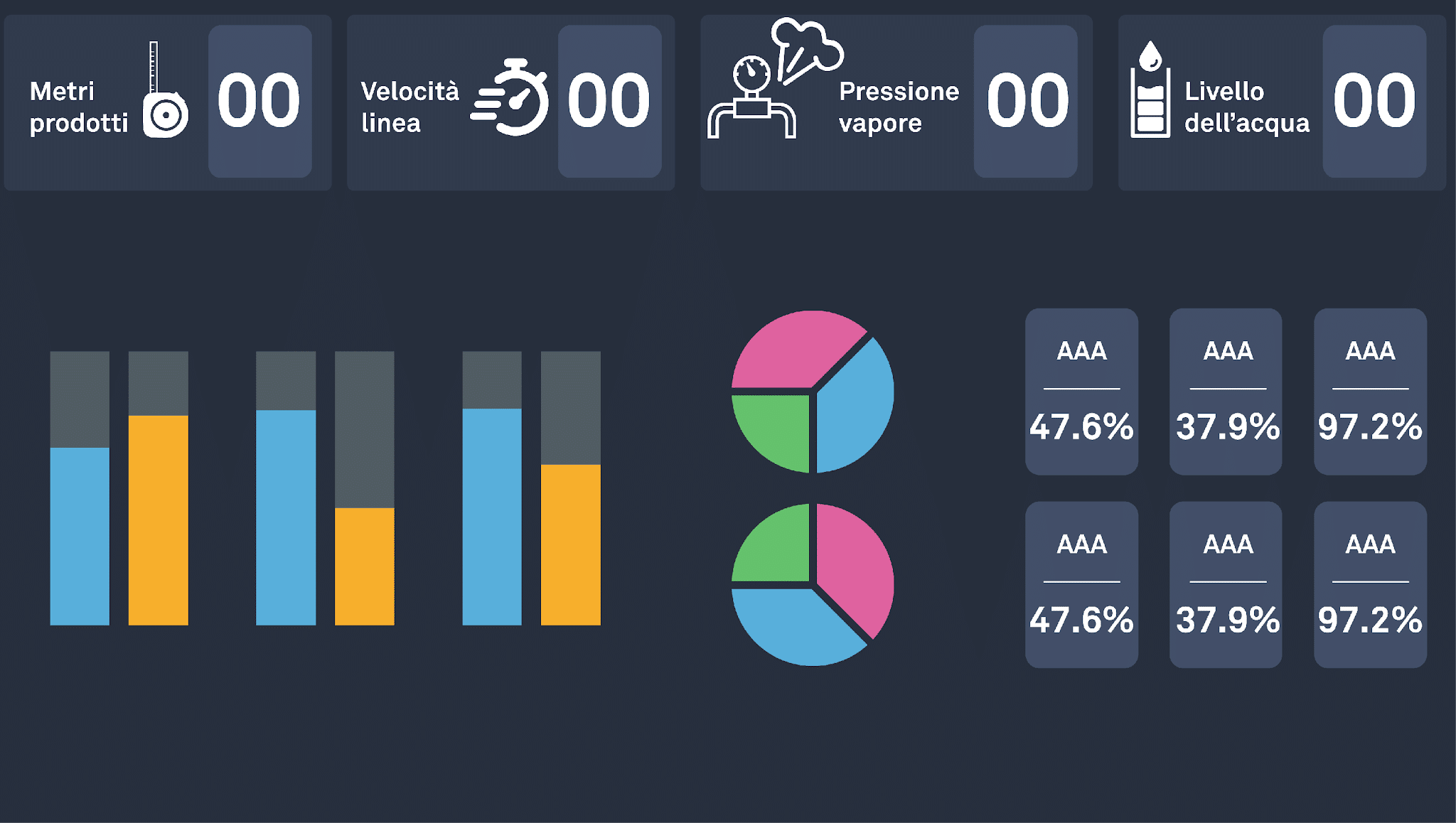

In addition to the Panel PC, the software is also installed on monitors distributed along the production line, which show the main monitoring data of each machine in real time, making the operating parameters visible and shared among all operators. Furthermore, the application is also available on tablets, allowing operators to move freely during the setup and control phases, always keeping all the essential information at hand.

The operational process begins with the reading of the barcode associated with the order: the operator scans it to identify the product to be produced, after which a pre-filled form opens on the Panel PC with the production “recipe”, where he can enter the quantities and view the parameters to be configured. The recipe can also be consulted and modified from a tablet, for even more flexible management.

During the setup, the operator is guided by video tutorials directly accessible from the device. Two levels of tutorials have been designed: a concise guide aimed at expert users, and a detailed step-by-step path designed for those with less experience, thus ensuring targeted support depending on the level of expertise.

Once the configuration is complete, the system verifies the accuracy of the operations performed: any errors or incomplete steps are reported, ensuring quality control before starting production.

Once the process is started, all the machine operating data are displayed in real time on the monitors, allowing for timely intervention in the event of anomalies. Key information such as meters produced, line speed, steam pressure and water level are also displayed on the tablet, which also provides a list of alerts and suggestions on how to resolve them, actively supporting the operator in managing the production cycle.

The implementation of the new solution has led to a profound cultural and operational change within the Aristoncavi production department. The technical skills, previously kept in a fragmented and personal way, are now shared and accessible to the entire team, thanks to the digitalization of recipes and the integration of interactive tutorials. This has made it possible to transform individual know-how into collective heritage, increasing the level of autonomy and operational safety of each individual employee.

One of the most significant results has been the overcoming of dependence on specific operators: each product can now be put into production regardless of who is at the workstation, ensuring continuity even in the event of shift changes, absences or staff rotations.

IIn parallel, setup times have been drastically reduced. The introduction of pre-set recipes and step-by-step guided tutorials allows operators – even the least experienced – to correctly configure the machine in much shorter times. The production line is thus made operational in a rapid and standardized way, minimizing inefficiencies and maximizing the overall productivity of the plant.

The partnership with AzzurroDigitale has proven to be extremely effective from the very first moments, an excellent feeling has been created. They responded perfectly and very quickly to our needs.

Write to us about what you need! Together we will identify the best solution for your needs.

"*" indicates required fields

Via della Croce Rossa, 36

35129 – Padua

* Applications sent to this email will not be considered